Meeting exact customer product dimensional, ductility, and performance specifications requires specialized alloy selection and engineered manufacturing. Our custom demister pads can be manufactured in a wide range of wire diameters, alloys, mesh densities, and product geometries under precise production and processing equipment capabilities. CWI produces the core products in-house that comprise the final product including wire, support rods and welding wire. Browse our selection of specialty alloys, such as Inconel® 625 below.

Comparing Shapes

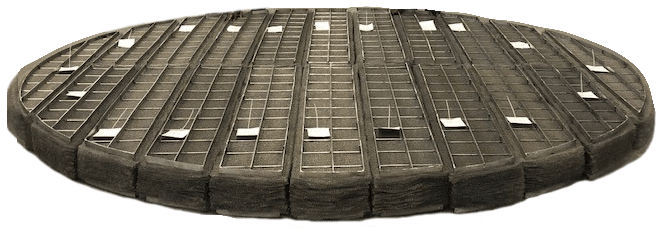

The shape of a mist eliminator is typically dictated by the geometry of the tank, vessel, or equipment into which it will be installed. Circular, rectangular, and ring shapes are the most common, and they are always manufactured according to each customer’s unique specifications or requirements. Each custom demister pad is fabricated based on the application, product dimensions, and mesh thickness required by the customer.

A circle is one of the most common shapes for mist eliminators. Large pads can be split into multiple sections to easily pass through manways.

Like round mist eliminators, rectangular pads can also be manufactured in multiple sections to pass through narrow manways.

Ring shaped demister pads feature a circular opening to accommodate tank piping.

Supporting Grid Structure

Custom demister pads can be manufactured as either one unit or individual sections. Just like its shape, the structure of a demister pad is typically dictated by its installation requirements or equipment setup. The number of sections constructed depends on the overall diameter of the pad and the size of the manway required to install the finished product. This can range from While it may not be necessary for small demister pads, larger ones often require top and bottom supports. This grid configuration adds strength and structural support to the pad, while also securing the mesh and preventing it from unfurling from the edges. The knitting wire, round bar, and welding wire used to make our demister pads is all manufactured by CWI facilities, ensuring you receive only the highest quality finished product.

CWI Tech-Mesh™ is available in a variety of different alloys to meet the needs of your application or equipment setup. 300 series stainless steel is a common choice for mist eliminators because it provides corrosion and rust resistance while still maintaining a long service life. We also offer specialty alloys such as Monel® 400 and Alloy 20 (20Cb3) for applications that require additional performance. Our copper alloys are a cutting-edge option for mesh.

Choosing the appropriate mesh density for your specific application, industry, or equipment is essential. Use the chart below to compare mesh densities and wire diameters.

| Central Wire | Wire Diameter | Mesh Density |

|---|---|---|

| CWI-USA-157 | 0.011" | 5.0 |

| CWI-USA-213 | 0.011" | 7.0 |

| CWI-USA-279 | 0.011" | 9.0 |

| CWI-USA-360 | 0.011" | 11.0 |

| CWI-USA-377 | 0.011" | 12.0 |

| CWI-USA-394 | 0.006" | 7.2 |

| CWI-USA-410 | 0.006" | 8.0 |

| CWI-USA-655 | 0.006" | 12.0 |