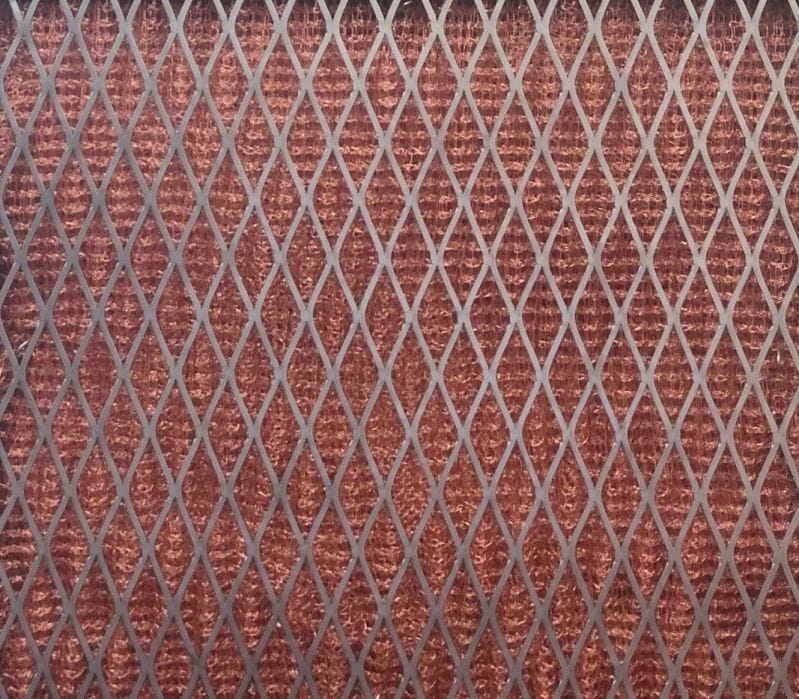

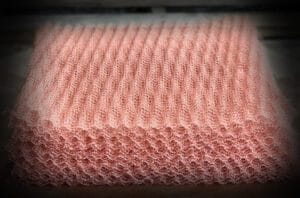

Need a different material for your bulk mesh or oil mist eliminator? Copper alloys are always available upon request. Copper alloys provide a number of benefits for your knitted wire mesh needs. Unlike other alloys, copper is both strong and pliable. A unique combination of high strength and high ductility makes copper ideal for mesh materials. Copper alloys have natural properties that can destroy a wide range of harmful microorganisms. Copper is resistant to corrosion and rust, which is key for all industries including refinery towers, food and beverage and filtration.

As an added benefit, CWI Tech-Mesh™ uses only made in the USA materials provided by other Central Wire factories. Having a close-knit supply chain means you can get the exact product you need without sacrificing your quality standards. Download a copy of our alloys guide for convenient referencing, and do not hesitate to contact us with any additional questions. Interested in specifying your own custom gas or oil mist eliminator? Visit our custom demister pad page for further information.

C101 copper is commonly used in a wide variety of engineering applications. This alloy offers high ductility and impact strength which makes it a versatile material. With high electrical and thermal conductivity, C101 is a popular choice for all types of electrical components and conductors.

Oxygen-free Copper

Electrolytic tough-pitch copper

C101

Applicable Specifications

- ASTM B1, B2, B8, B48, B272, B298, F68

- AMS 4700

- Federal QQ-W-343

Chemical Composition (Weight %)

| Cu* | Pb | Zn | Fe | P | Ag | As | O2 | Sb | Te | |

|---|---|---|---|---|---|---|---|---|---|---|

| Min | 99.99 | |||||||||

| Max | 0.0005 | 0.0001 | 0.0010 | 0.0003 | 0.0025 | 0.0005 | 0.0005 | 0.0004 | 0.0002 |

Typical Uses

- Automotive Rectifiers

- Bus Bars

- Bus Conductors

- Coaxial Cable

- Vacuum Seals

- Transistor Component Bases

C102

Chemical Specifications

CU: 99.95%

CU: 99.95%

Resistivity (Ohm.cmil/ft): 10.371

Resistivity (Ohm mm2/m): 0.720

Density: .322

Melting Point: 1065 C/1949 F

Thermal Conductivity @ 212° F: 388 W/m.K

Thermal Expansion @ 212° F: 9.4 x 10-6

Designation/Specification: ASTM B1, B2, B3, B33, B49

Mechanical Properties

| Tensile | Yield | Elongation | |||

|---|---|---|---|---|---|

| O61 | Soft | 25-35 KSI | 15-25 KSI | 35% min | |

| H00 | 1/8 HD | 30-40 KSI | 18-25 KSI | 20% min | |

| H01 | 1/4 HD | 35-45 KSI | N/A | 15% min | |

| H02 | 1/2 HD | 40-50 KSI | N/A | 10% min | |

| H03 | 3/4 HD | 45-55 KSI | N/A | 5% min | |

| H04 | Full HD | 50-60 KSI | N/A | 1.5% min | |

| H08 | Spring | 60-70 KSI | N/A | 1.5% min |

Chemical Composition (Weight %)

| Cu* | Pb | Zn | Fe | P | Ag | As | O2 | Sb | Te | |

|---|---|---|---|---|---|---|---|---|---|---|

| Min | 99.95 | |||||||||

| Max | 0.0010 |

Resistance Specifications:

Note: Diameter is governed by resistance unless specified by the customer.

Material annealing temperature for soft and 1/8HD material is 850 degrees Fahrenheit (454.44C)

.0226″ (23ga) and larger diameter: +/-.0005″ to .001″

.0126″ (23ga) to .0201″ (24ga): +/-.003″

.0025″ (42ga) to .0113″ (29ga): +/-.0002″

C110

Chemical Specifications

CU: 99.90%

Resistivity (Ohm.cmil/ft): 10.371

Resistivity (Ohm mm2/m): 0.720

Density: .322

Melting Point: 1065 C/1949 F

Thermal Conductivity @ 212° F: 388 W/m.K

Thermal Expansion @ 212° F: 9.4 x 10-6

Designation/Specification: ASTM B1, B2, B3, B33, B49

Mechanical Properties

| Tensile | Yield | Elongation | |||

|---|---|---|---|---|---|

| O61 | Soft | 25-35 KSI | 15-25 KSI | 35% min | |

| H00 | 1/8 HD | 30-40 KSI | 18-25 KSI | 20% min | |

| H01 | 1/4 HD | 35-45 KSI | N/A | 15% min | |

| H02 | 1/2 HD | 40-50 KSI | N/A | 10% min | |

| H03 | 3/4 HD | 45-55 KSI | N/A | 5% min | |

| H04 | Full HD | 50-60 KSI | N/A | 1.5% min | |

| H08 | Spring | 60-70 KSI | N/A | 1.5% min |

Chemical Composition (Weight %)

| Cu* | Pb | Zn | Fe | P | Ag | As | O2 | Sb | Te | |

|---|---|---|---|---|---|---|---|---|---|---|

| Min | 99.90 | |||||||||

| Max |

Resistance Specifications:

Note: Diameter is governed by resistance unless specified by the customer.

Material annealing temperature for soft and 1/8HD material is 850 degrees Fahrenheit (454.44C)

.0226″ (23ga) and larger diameter: +/-.0005″ to .001″

.0126″ (23ga) to .0201″ (24ga): +/-.003″

.0025″ (42ga) to .0113″ (29ga): +/-.0002″

Submit a Quote Request