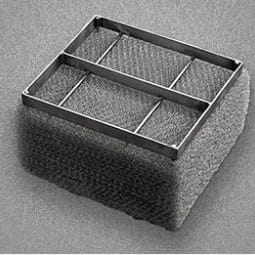

In addition to traditional 300 series stainless steel, we have the capability to produce knitted wire mesh products in specialty alloys such as Monel® 400. Known for its ability to withstand harsh environments and extreme working conditions, CWI Tech-Mesh™ is specifically engineered to endure all the challenges faced by oil and gas industries. Whether you are replacing an existing unit or specifying a custom solution, Central Wire offers only the highest quality finished products.

Need a different material for your oil mist eliminator? Inconel® alloys are always available upon request. Visit our stainless steel alloys page for additional information about our 304, 316, 321, and 347 stainless steel. As an added benefit, CWI Tech-Mesh™ uses only made in the USA materials provided by other Central Wire factories. Having a close-knit supply chain means you can get the exact product you need without sacrificing your quality standards.

Download a copy of our alloys guide for convenient referencing, and do not hesitate to contact us with any additional questions. Interested in specifying your own custom gas or oil mist eliminator? Visit our custom demister pad page for further information.

CWI Nickel Specialty Series Monel® 400 is a nickel-copper alloy with superior corrosion resistance in a wide variety of media. UNS N04400 – Ni: 63.0-70.0% and Cu: 28.0-34.0% with full chemistry to ASTM B164

CWI Nickel Prime Series 20 (20Cb3) is an iron-based, austenitic alloy with outstanding corrosion resistance in a number of different environments. It also offers an excellent resistance to hot sulfuric acid. UNS N08020 – Cr: 19.0-21.0%, Cu: 3.0-4.0%, Mo: 2.0-3.0%, Ni: 32.0-38.0% and Cb: 8xC – 1.0% with full chemistry to ASTM B471, B473 and B475

CWI Nickel 200 (UNS N02200) is a commercially pure (99% minimum) nickel alloy which has good mechanical properties and excellent corrosion resistance in various environments with chemistry to ASTM B160.

| Alloy | C | Mn | Si | P | S | Cr | Ni | Mo | Cu | Co | Al | Ti | Fe | Cb | V | W | Other Requirements |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alloy 20 (20Cb3) | 0.050% max | 2.00% max | 1.00% max | 0.035% max | 0.010% max | 19.0-21.0% | 32.0-38.0% | 2.0-3.0% | 3.0-4.0% | Bal | (Cb+Ta): 8xC to 1.0% ASTM B471, B473 & B475 |

||||||

| Duplex 2205 | 0.03% max | 2.0% max | 1.0% max. | 0.03% max | 0.02% max | 21-23% | 4.5-6.5% | 2.5-3.5% | N: 0.14-0.20% | ||||||||

| Hastelloy C-276 | 0.010% max | 1.00% max | 0.08% max | 0.025% max | 0.010% max | 14.5-16.5% | Bal | 15.0-17.0% | 0.50% max | 2.50% max | 4.0-7.0 | 0.30% max | 3.00-4.50% | N: 0.10% max ASTM B574 (chemistry only) |

|||

| Inconel® 600 | 0.050& max | 0.50-1.00% | 0.20-0.50% | 0.020% max | 0.010 | 14.0-17.0% | 72.0% min | 0.50% max | 0.50% max | 0.30% max | 0.35% max | 0.50% max | 6.0-8.0% | 1.00% max | Ta: 0.05% max; (Cb+Ta): 1.0% max | ||

| Inconel® 601 | 0.060% max | 1.00% max | 0.50% max | 0.015% max | 0.010$ max | 21.0-25.0% | 58.0-63.0% | 1.00% max | 1.0-1.70% | 0.60% max | Bal | B: 0.006% max | |||||

| Inconel® 625 | 0.10% max | 0.50% max | 0.50% max | 0.015% max | 0.010% max | 20.0-23.0% | 58.0% min | 8.0-10.0% | 1.00% max | 0.40% max | 0.40% max | 5.0% max | (Cb+Ta): 3.15 to 4.15% AMS 566 (chemistry only) |

||||

| Inconel® 718 | 0.020-0.060% | 0.30% max | 0.30% max | 0.014% max | 0.010% max | 17.0-20.50% | 50.0-55.0% | 2.85-3.25% | 0.30% max | 0.40% maxq | 0.40-0.70% | 0.75-1.15% | 15.0-21.0% | 5.00-5.50% | |||

| Incoloy® 825 | 0.05% max | 1.0% max | 0.5% max | 0.020% max` | 0.015% max | 19.5-23.5% | 38.0-46.0% | 2.5-3.5% | 1.5-3.0% | 1.50% max | 0.20% max | 0.60-1.20 | 22.0% max | ||||

| Monel® 400 | 0.025% max | 1.25% max | 0.50% max | 0.020% max | 0.020% max | 63.0-70.0% | 28.0-34.0% | 1.00% max | 0.10% max | 2.50% max | Pb & Sn: 0.006% max, Zn: 0.02% max ASTM B164 (chem only); QQ-N-281 |

||||||

| Nickel 200 | 0.020% max | 0.35% max | 0.20% max | 0.010% max | 0.05% max | 99.0% min | 0.01% max | 0.035% max | Report | 0.17% max | 0.08% max | 0.15% max | 0.0002% max | As: 0.001% max, Sb: 0.001% max Mg: 0.05% max ASTM B160 (chemistry only) |

Submit a Quote Request